Printer Calibration Models for Autodesk Fusion

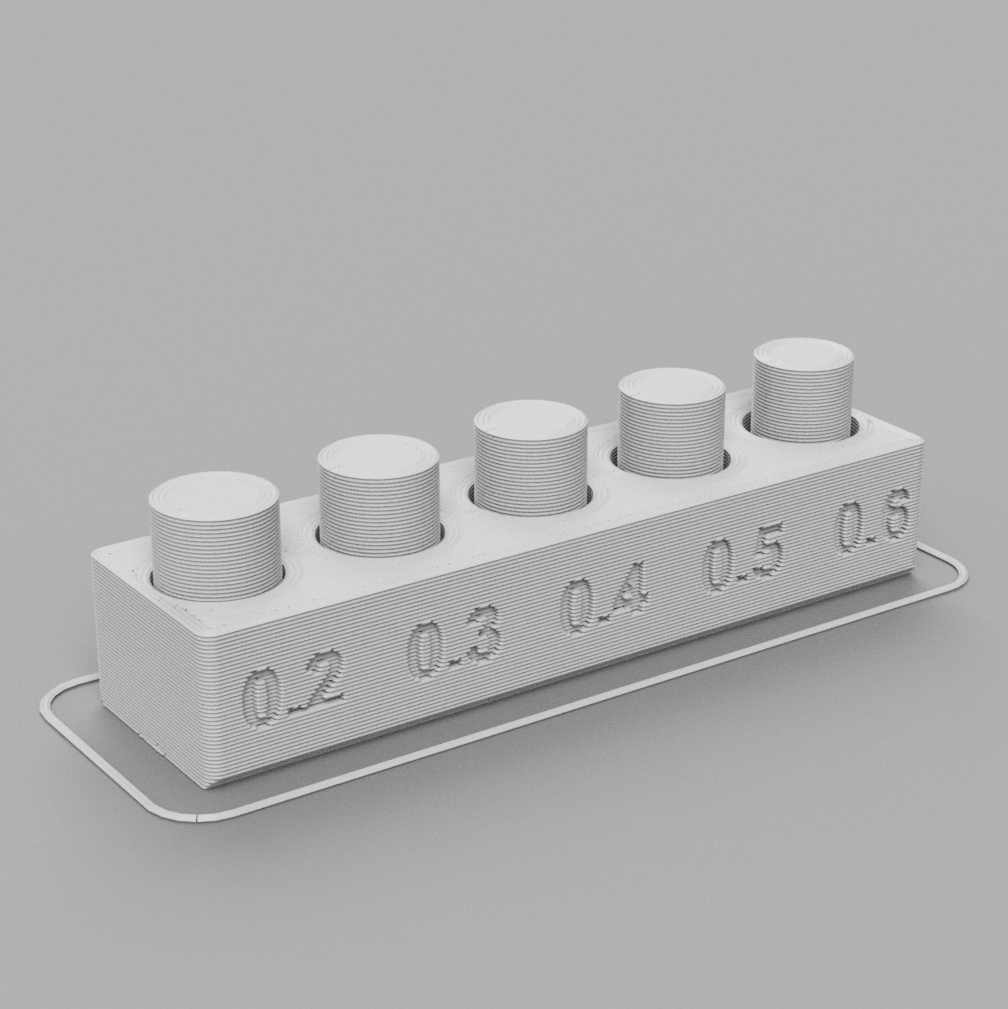

Complete either the quick General Test with a max score of 5 points. Or complete all 8 prints with a max score of 35 points.| Target | Measured X | Measured Y | X Error | Y Error |

|---|---|---|---|---|

| 25 | 24.82 | 24.69 | 0.18 | 0.31 |

| 20 | 19.93 | 19.75 | 0.07 | 0.25 |

| 15 | 14.99 | 14.82 | 0.01 | 0.18 |

| 10 | 10.01 | 9.85 | 0.01 | 0.15 |

| 5 | 4.84 | 4.84 | 0.16 | 0.16 |

| Avg Err: | 0.082 | 0.21 | ||

| Average of avg. X and avg. Y error | 0.146 | |||

| Difference between avg. X and avg. Y error | 0.128 |

Record a "1" if the magnitude of the overall average error is greater than 0.40mm.

Record a "2" if the magnitude of the overall average error is between 0.31 and 0.40mm.

Record a "3" if the magnitude of the overall average error is between 0.21 and 0.30mm.

Record a "4" if the magnitude of the overall average error is 0.11 and 0.20mm.

Record a "5" if the magnitude of the overall average error is between 0.0 and 0.10mm.

While it is not explicitly scored in this evaluation, this test also reveals the presence of backlash (or incorrectly calibrated motion systems) when the average X and average Y errors are compared. A significant difference between the two values indicates a problem.